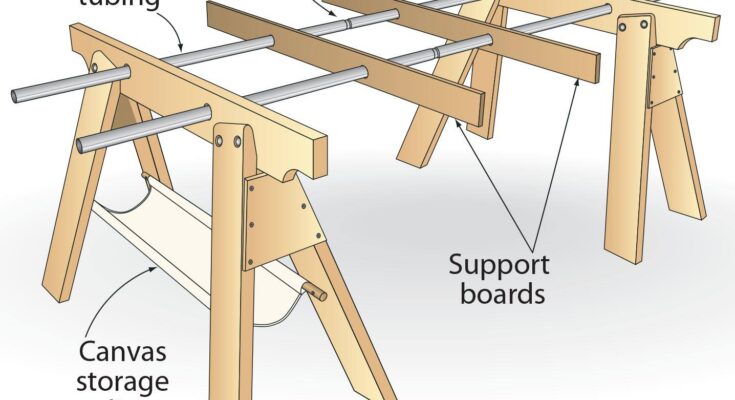

This detailed illustration presents a clever and potentially space-saving design for a pair of collapsible sawhorses, leveraging readily available materials like chain-link fence tubing for a key structural component. The core function of these sawhorses, like any other, is to provide stable elevated support for various work tasks, such as cutting lumber, assembling projects, or holding materials for painting or finishing. However, the specific construction methods and added features showcased here offer unique advantages in terms of portability, adjustability, and utility.

The foundation of the system comprises two individual sawhorses, each constructed primarily from wooden members. The legs of these sawhorses exhibit a hinged design, a common characteristic of collapsible sawhorses. This hinging mechanism allows the legs to fold inwards towards the main frame of the sawhorse when not in use, significantly reducing the overall footprint for convenient storage in tight spaces like workshops, garages, or even the back of a vehicle. The hinges appear to be secured with bolts or pins, allowing for both stability when deployed and ease of folding when needed. The splayed angle of the legs when open provides a wide and stable base, crucial for supporting potentially heavy or unwieldy workpieces. Notches or cutouts are visible on the top horizontal supports of the sawhorses, likely designed to accommodate the chain-link fence tubing securely.

The most distinctive element of this design is the use of chain-link fence tubing as the primary horizontal support connecting the two sawhorses. Instead of traditional solid wooden beams or metal bars, these hollow, cylindrical tubes span the distance between the two sawhorse frames. This choice of material likely aims to achieve a balance between strength and weight. Chain-link fence tubing is relatively lightweight, making the entire system easier to transport. Furthermore, its inherent rigidity, especially when multiple tubes are used in parallel, can provide sufficient support for many common woodworking or DIY tasks. The diagram shows at least three parallel tubes connecting the sawhorses, increasing the overall load-bearing capacity and providing a wider support area.

The connection between the chain-link fence tubing and the wooden sawhorses is facilitated by tubing joints. These fittings are critical for the structural integrity of the entire setup. The diagram highlights one such joint, suggesting a design that allows for the secure insertion and locking of the tubing into the wooden frame. The nature of these joints could vary; they might involve sleeves, brackets with tightening mechanisms, or other types of fasteners that ensure the tubing remains firmly in place during use and can be easily detached for disassembly and storage of the individual sawhorses. The ability to detach the tubing from the sawhorses further enhances the portability and modularity of the system.

Resting atop the chain-link fence tubing are support boards. These wooden planks serve as the direct contact surface for the material being worked on. The use of multiple, separate support boards offers a degree of adjustability. The spacing between these boards can be altered depending on the size and shape of the workpiece, allowing for optimized support and preventing sagging or instability. This modular approach is more versatile than a single, fixed tabletop.

A practical addition to one of the sawhorses is the canvas storage sling. This fabric pouch is suspended beneath the top frame of the sawhorse, creating a convenient storage space for tools, clamps, power cords, or other accessories that might be needed during a work session. This integrated storage solution helps keep the workspace organized and ensures that essential items are readily accessible, improving efficiency and reducing clutter. The sling appears to be attached to the wooden frame with fasteners or straps, providing a flexible and easily accessible storage area that doesn’t interfere with the primary function of the sawhorses.

In conclusion, this design for collapsible sawhorses demonstrates an innovative approach to creating a portable, adjustable, and multi-functional work support system. By utilizing lightweight chain-link fence tubing as connecting supports and incorporating a canvas storage sling, it addresses common needs in a workshop environment while also prioritizing ease of storage and transportation. The modularity of the support boards further enhances its adaptability to various tasks and workpiece sizes, making it a potentially valuable asset for DIY enthusiasts, woodworkers, and contractors alike.