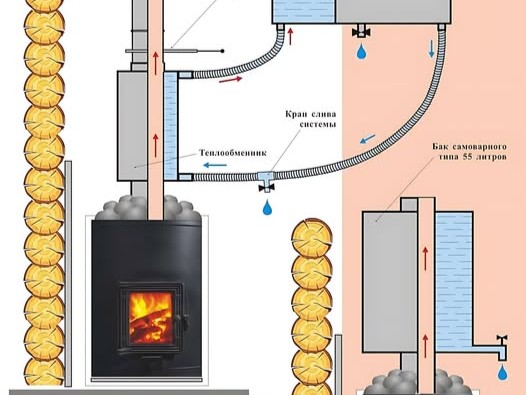

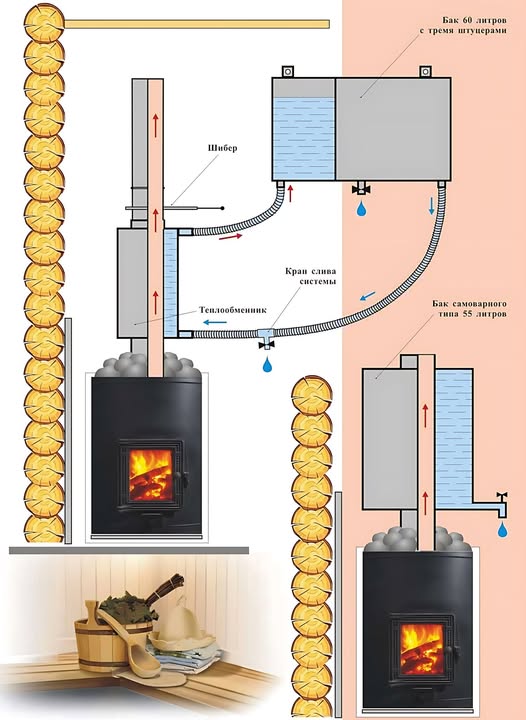

This detailed illustration presents two distinct methods for heating water in a sauna environment, both utilizing a wood-burning stove as the primary heat source. The left configuration showcases an indirect heating system employing a heat exchanger integrated with the stove’s chimney, while the right configuration depicts a direct heating system where the water tank is heated directly by the fire. Understanding these contrasting approaches is crucial for sauna builders and enthusiasts to select the most suitable and efficient method for their needs, considering factors like water volume, heating speed, temperature regulation, and overall system complexity.

Left Configuration: Indirect Water Heating via Chimney Heat Exchanger

The left side of the illustration details a more elaborate system designed for heating a larger volume of water indirectly. The core components include:

- Insulated Wood-Burning Stove: The foundation of the system is a robust, insulated wood-burning stove, clearly indicating the combustion of wood as the energy source. The insulation suggests an effort to maximize heat transfer to the intended areas (the heat exchanger and the sauna room itself) while minimizing heat loss. The visible flames within the firebox confirm the active heating process.

- Chimney with Integrated Heat Exchanger (“Теплообменник”): Rising from the stove is a chimney pipe, a necessary conduit for expelling hot exhaust gases. However, a significant section of this chimney is encased within a rectangular heat exchanger. This crucial component facilitates the transfer of thermal energy from the hot flue gases to the water circulating within it. The blue arrows clearly depict the intake of cooler water into the heat exchanger, typically drawn from the bottom of the storage tank due to natural convection (cooler water is denser). As this water flows through the exchanger, it absorbs heat from the hot chimney gases, indicated by the red arrows showing the outflow of heated water towards the storage tank. This indirect method prevents the water from coming into direct contact with the fire or combustion byproducts, ensuring its cleanliness.

- Chimney Damper (“Шибер”): Positioned in the chimney pipe above the heat exchanger is a damper or shut-off valve. This adjustable plate controls the flow of exhaust gases through the chimney. By partially closing the damper, the residence time of the hot gases within the heat exchanger can be increased, leading to more efficient heat transfer to the water. However, excessive closure can impede proper draft and lead to incomplete combustion, so careful adjustment is necessary.

- Insulated Storage Tank (“Бак 60 литров с тремя штуцерами”): Located above and to the side of the stove is a relatively large, 60-liter storage tank. The insulation surrounding this tank minimizes heat loss, allowing the heated water to remain hot for extended periods. The presence of three connections (“штуцерами”) indicates the versatility of this tank. The top connection receives the heated water from the heat exchanger (red arrow), promoting stratification within the tank (hotter water rises). The bottom connection serves as the intake for cooler water to be drawn back into the heat exchanger (blue arrow), creating a natural thermosiphon circulation loop. The third connection, not directly involved in the heating loop, likely acts as an outlet for the hot water to be used for various purposes within the sauna, such as rinsing or generating steam.

- System Drain Valve (“Кран слива системы”): A drain valve is strategically placed at the lowest point of the heat exchanger. This allows the entire water heating system to be drained for maintenance, cleaning, or, most importantly, to prevent freezing and potential damage during periods of non-use in cold climates.

- Fuel Source and Context: A neatly stacked pile of chopped firewood to the left serves as a visual reminder of the fuel powering the system. In the foreground, traditional sauna accessories like a wooden bucket, ladle, felt hat, and towels further contextualize the illustration within a sauna setting.

Right Configuration: Direct Water Heating via Stove-Mounted Tank

The right side illustrates a simpler and more direct approach to heating water:

- Wood-Burning Stove: Similar to the left configuration, a wood-burning stove provides the heat source.

- Directly Heated Tank (“Бак самоварного типа 55 литров”): In this setup, a 55-liter water tank, described as “samovar type,” is positioned directly on or integrated into the top of the stove. This implies that the bottom surface of the tank is in direct contact with the heat generated by the fire, leading to rapid and efficient heat transfer to the water. The red arrows within the tank visually represent the direct heating process. The “samovar type” designation likely refers to a design where the tank is specifically engineered to withstand and efficiently absorb the direct heat from the stove, perhaps with internal flues or a specific shape to maximize heat exchange.

- Hot Water Outlet Tap: A simple tap or valve is located at the bottom of the tank, serving as the outlet for the heated water. This suggests a system where hot water is drawn directly from the heated tank as needed.

- Fuel Source: A stack of firewood is also present on the right, indicating the fuel source for this direct heating method.

Comparative Analysis and Implications for Sauna Design:

The two configurations presented highlight fundamental differences in sauna water heating:

- Heating Efficiency and Speed: Direct heating (right) is generally faster and more efficient for heating a smaller volume of water because the tank directly absorbs the intense heat from the fire. Indirect heating (left) takes longer to heat a larger volume but offers more consistent temperature and potentially better control.

- Water Quality: Indirect heating keeps the water separate from combustion byproducts, ensuring cleaner hot water. Direct heating might introduce some soot or residue if the tank design isn’t optimal or if the stove isn’t properly maintained.

- Water Volume and Usage: The 60-liter insulated tank in the indirect system provides a larger reserve of hot water suitable for multiple users or extended sauna sessions. The 55-liter direct heating tank is better suited for smaller groups or shorter sessions.

- Temperature Control: Indirect systems with a chimney damper offer a degree of temperature regulation by controlling the heat transfer rate. Direct heating is more closely tied to the intensity of the fire.

- System Complexity and Cost: The indirect system with a heat exchanger, storage tank, and circulation loop is more complex and likely more expensive to install than the simpler direct heating setup.

- Safety Considerations: Both systems require careful installation and maintenance to ensure safe operation. Direct heating tanks need to be robust enough to withstand direct heat, while indirect systems need proper sealing to prevent leaks in the heat exchanger.

The choice between these two systems depends heavily on the specific needs and preferences of the sauna owner. For saunas with frequent use and a demand for larger volumes of consistently hot water, the indirect system with a storage tank offers advantages. For smaller saunas or those where rapid heating of a smaller quantity of water is sufficient, the direct heating method provides a simpler and potentially more cost-effective solution. The illustration provides a valuable visual comparison to aid in this decision-making process.