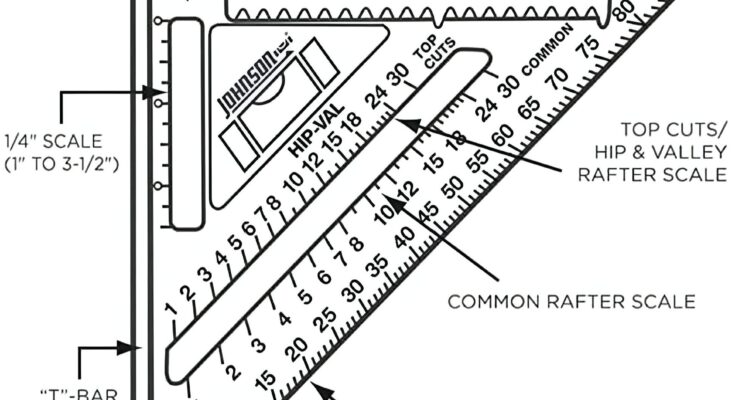

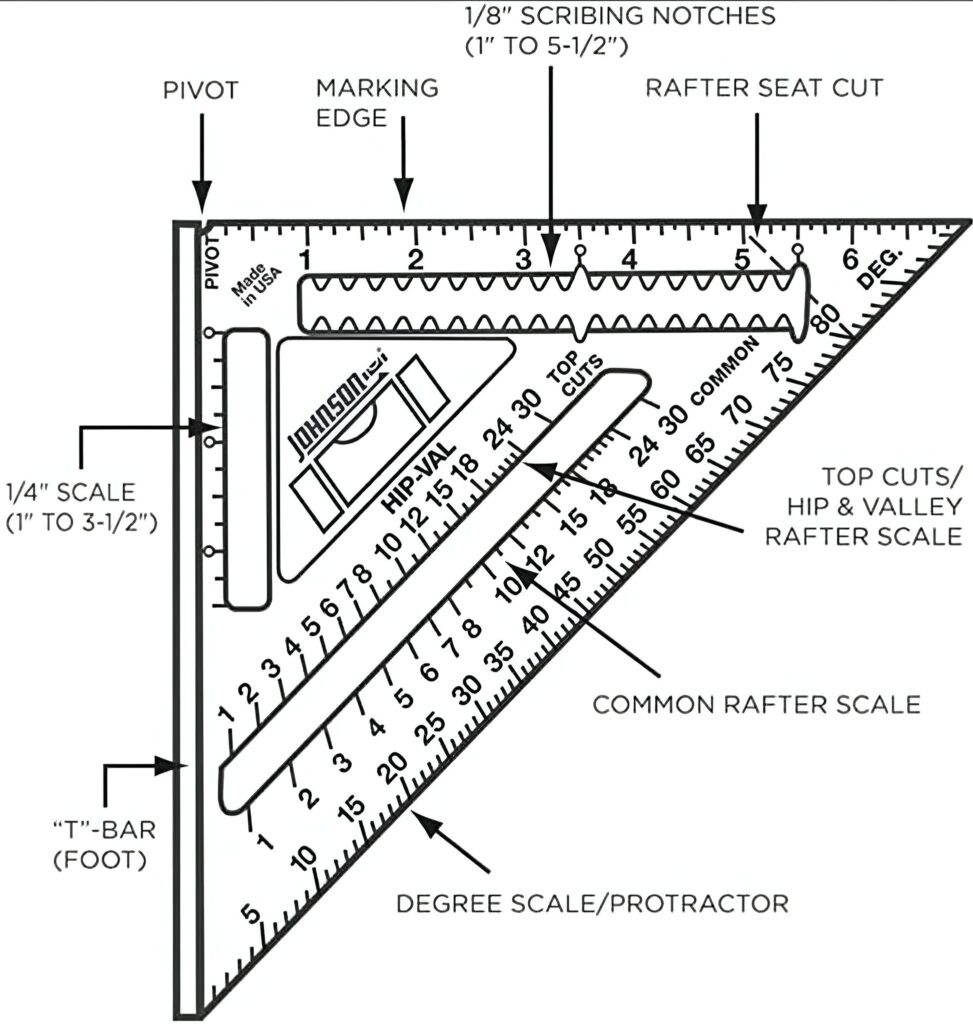

This detailed diagram meticulously dissects the anatomy and functionality of the speed square, a seemingly simple triangular hand tool that stands as a cornerstone of carpentry and construction. Often referred to as a rafter square or Swanson square (after one of its popular manufacturers), this compact tool transcends its basic geometric shape, offering a remarkable array of applications for marking precise angles, ensuring square cuts, and simplifying complex roof framing calculations. Its intuitive design and robust construction have made it an indispensable companion for both seasoned professionals and enthusiastic DIYers.

At its core, the speed square is a right-angled isosceles triangle, typically crafted from durable aluminum alloy. Its inherent 90-degree angle, formed by the “T”-bar (foot) and the marking edge, serves as a reliable reference for establishing squareness in various woodworking tasks, from cross-cutting lumber to aligning components for assembly. The robust nature of the material ensures accuracy and longevity, even under the demanding conditions of a construction site.

The “T”-bar (foot), also known simply as the foot, is the shorter of the two legs forming the right angle. This edge is designed to be held firmly against the edge of the workpiece, providing a stable and consistent reference point for all subsequent markings and cuts. Its straightness and precision are paramount to the accuracy of the measurements taken with the square.

The marking edge, the longer of the two legs forming the right angle, is the primary surface against which pencils, scribes, or knives are guided to create lines on the workpiece. Along this crucial edge are often found precisely etched ruler markings, allowing the speed square to double as a measuring tool for short distances. Furthermore, the presence of 1/8″ scribing notches (1″ to 5-1/2″) and 1/4″ scale (1″ to 3-1/2″) significantly enhances its utility. These precisely spaced notches enable the user to quickly and accurately mark parallel lines at consistent intervals from the edge of the board. By placing the pencil tip in the desired notch and sliding the square along the edge, multiple parallel lines can be drawn with ease and precision, a task frequently encountered in layout work and ripping boards.

The corner where the “T”-bar and the marking edge meet is the pivot point. This corner is strategically designed to be placed against the edge of the material when marking angles using the integrated protractor scale. By holding this pivot firmly and rotating the square, the desired angle can be easily aligned with the edge of the workpiece for accurate marking.

The degree scale/protractor, a fan-shaped series of markings along the hypotenuse (the longest edge) of the triangle, transforms the speed square into a versatile angle-marking tool. Ranging from 0 to 90 degrees, this scale allows for the direct layout of any desired angle. By pivoting the square and aligning the appropriate degree marking with the edge of the lumber, precise angled lines can be drawn for bevel cuts, miters, and other angled joinery.

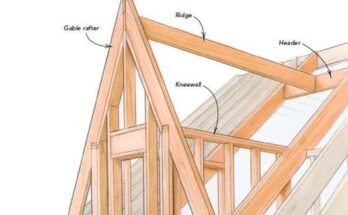

Beyond basic squaring and angle marking, the speed square truly shines in its application to roof framing. The presence of dedicated scales for common rafters and top cuts/hip & valley rafters streamlines the often-complex calculations involved in roof construction.

The common rafter scale, typically found along one of the longer edges adjacent to the hypotenuse, is calibrated to directly indicate the length of a common rafter per foot of horizontal run, based on the roof’s pitch (rise over run). By aligning the pivot with the edge of the top plate and rotating the square to the desired pitch marking, the corresponding rafter length can be read directly from the scale.

The top cuts/hip & valley rafter scale, often located on the opposite side of the common rafter scale, serves a dual purpose. It assists in determining the angle for the rafter seat cut, the crucial notch where the rafter rests on the top plate, ensuring proper load transfer. Additionally, the HIP-VAL markings on this scale provide the necessary angles for cutting hip and valley rafters, which run diagonally to the corners of the roof and require more complex angle calculations. The TOP CUTS markings specifically aid in determining the angle of the cut at the peak of the rafter where it meets the ridge board.

In conclusion, the speed square is far more than just a right-angled triangle. It is a meticulously designed multi-tool that integrates the functions of a square, ruler, scribing guide, protractor, and rafter angle calculator into a single, compact, and durable instrument. Its intuitive design and the wealth of information etched onto its surface make it an indispensable “cornerstone” tool for carpenters and builders, enabling accuracy, efficiency, and precision in a wide range of woodworking and construction tasks, particularly in the realm of roof framing.